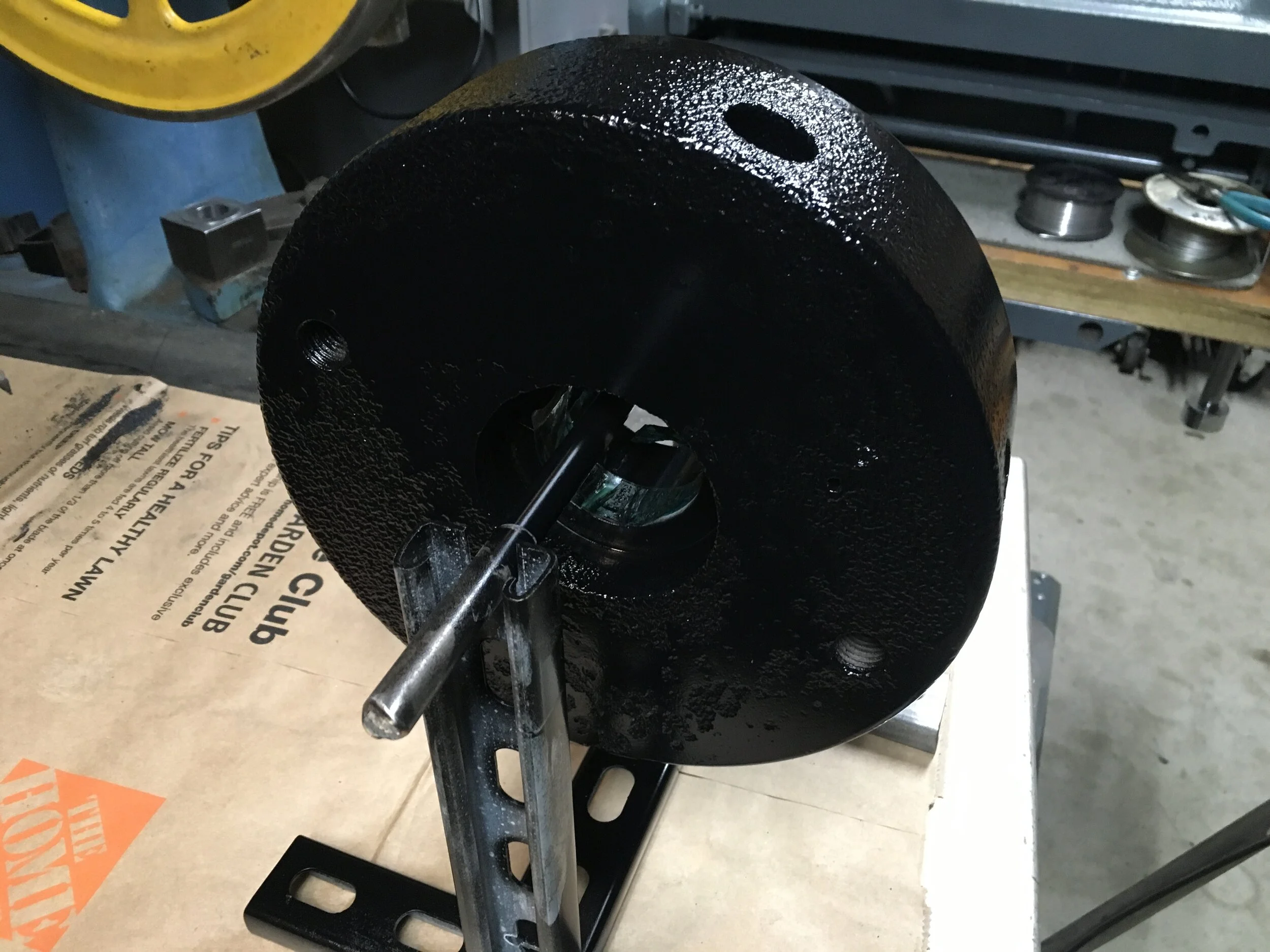

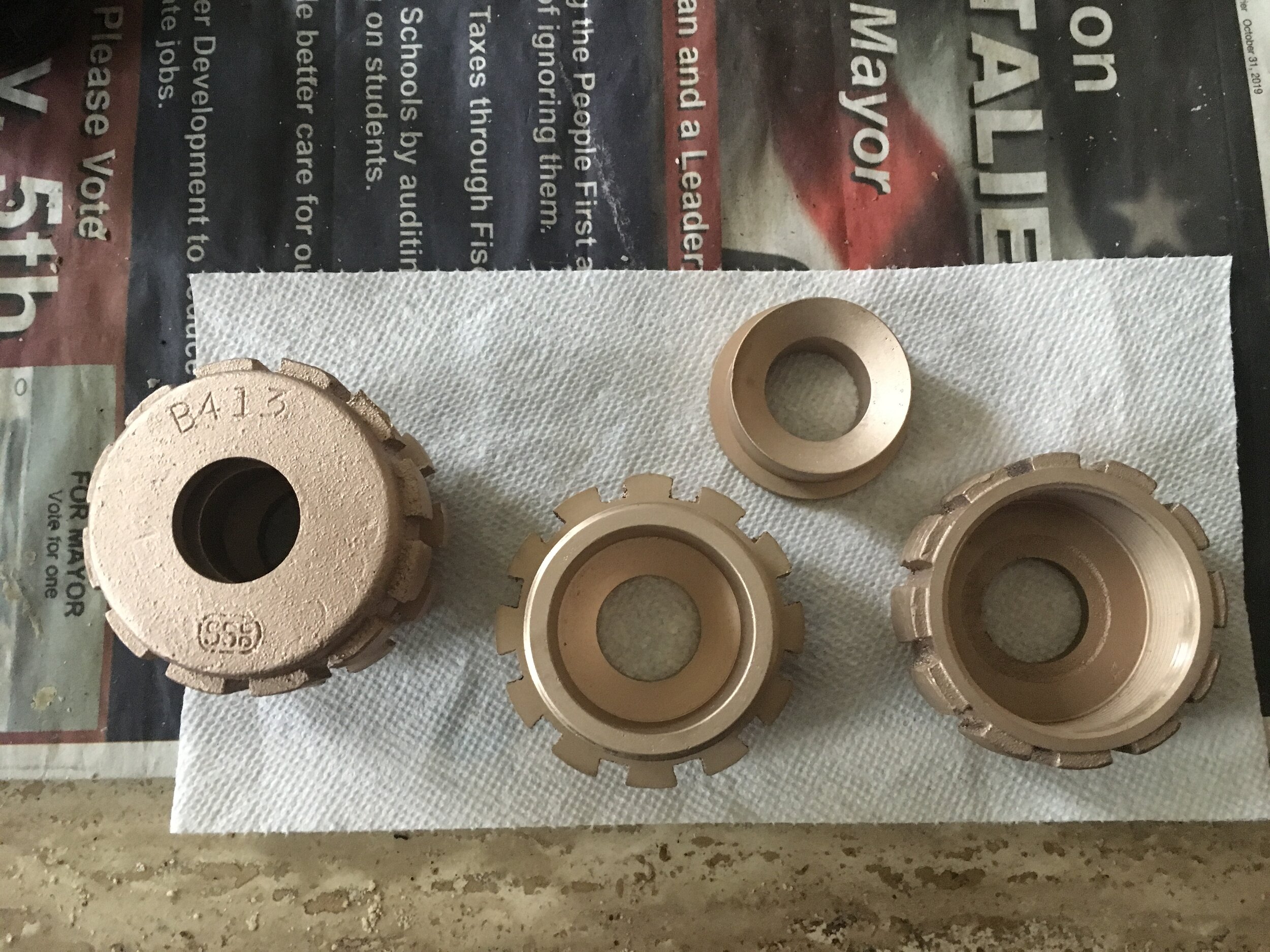

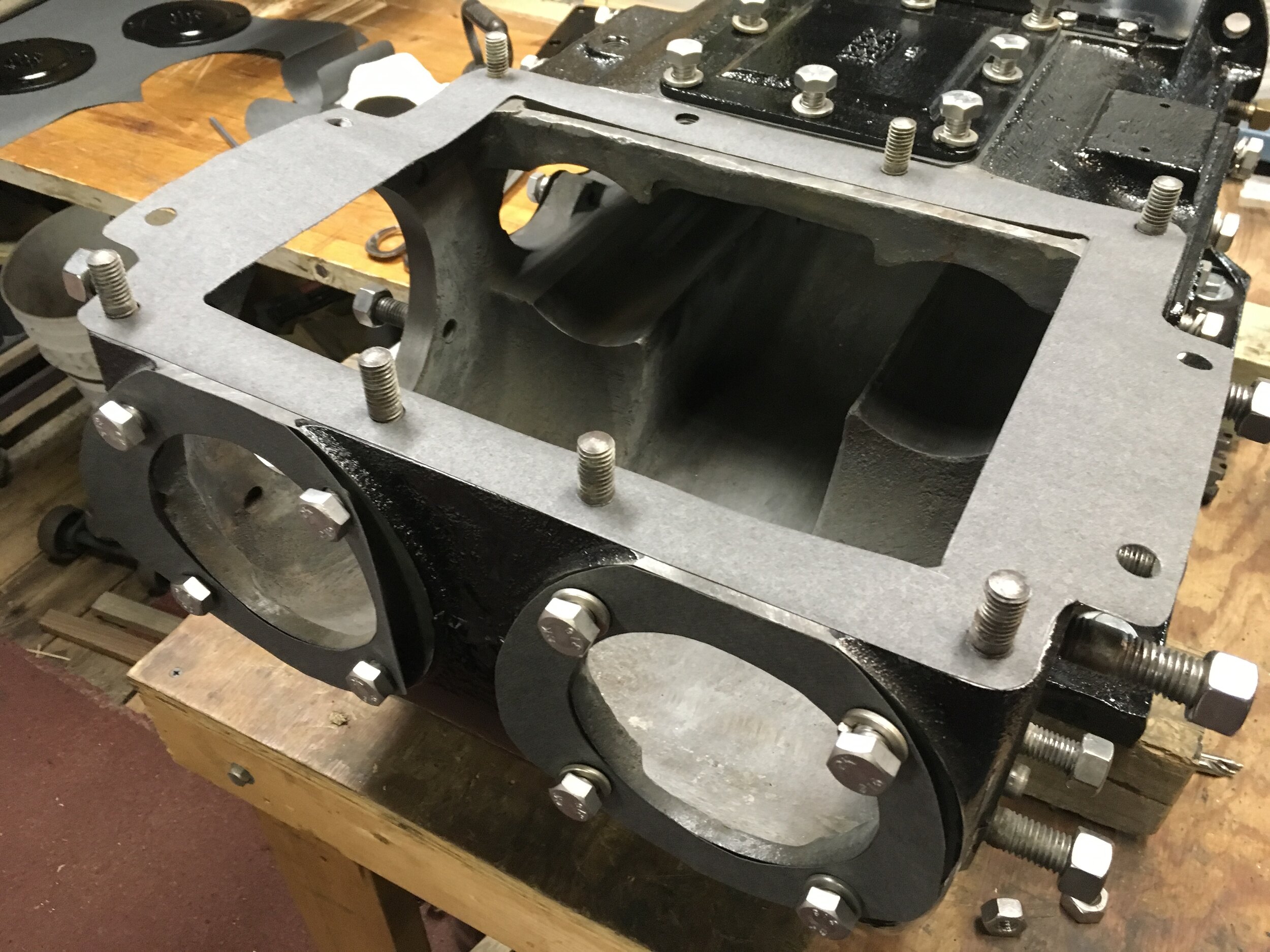

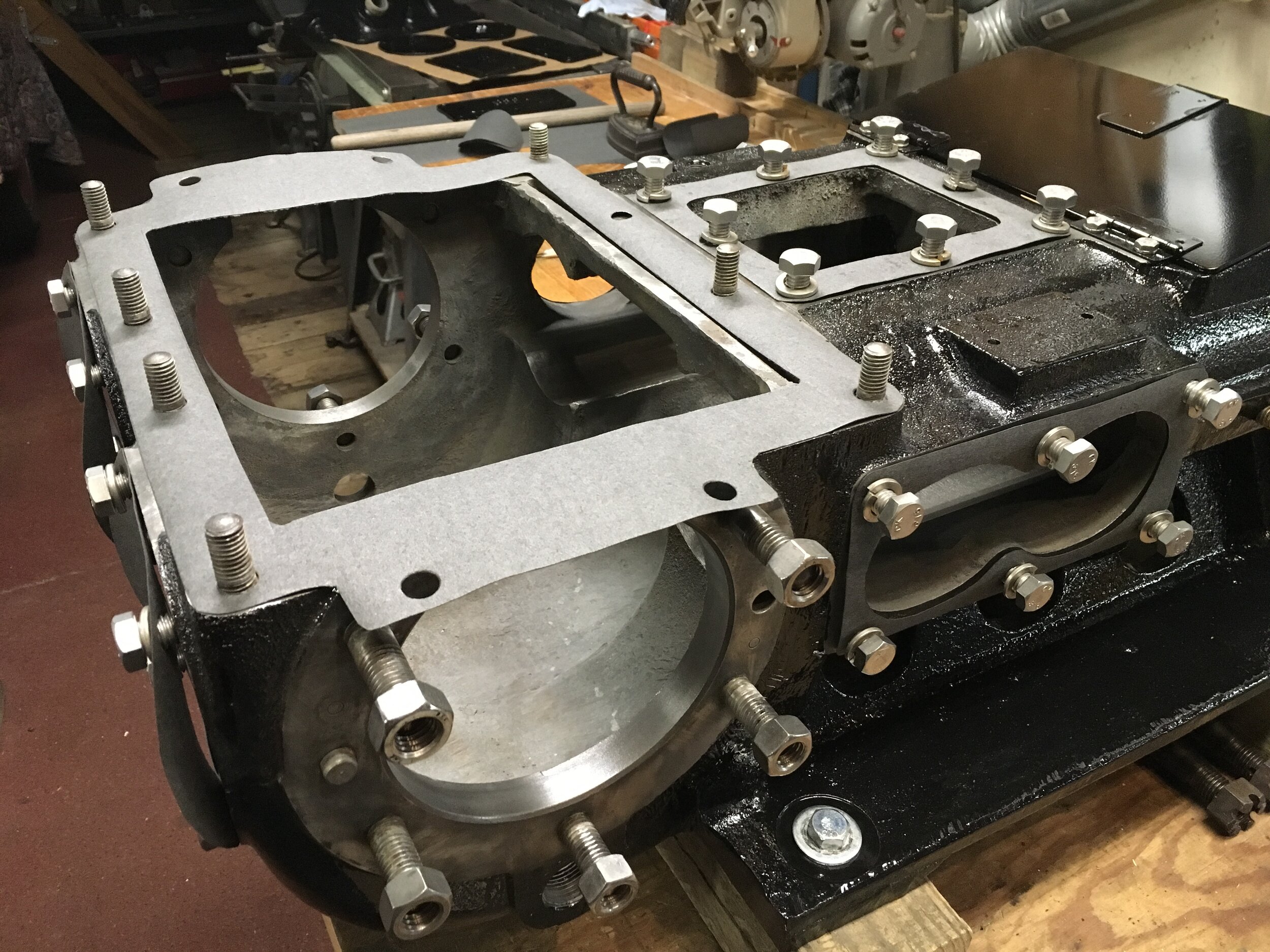

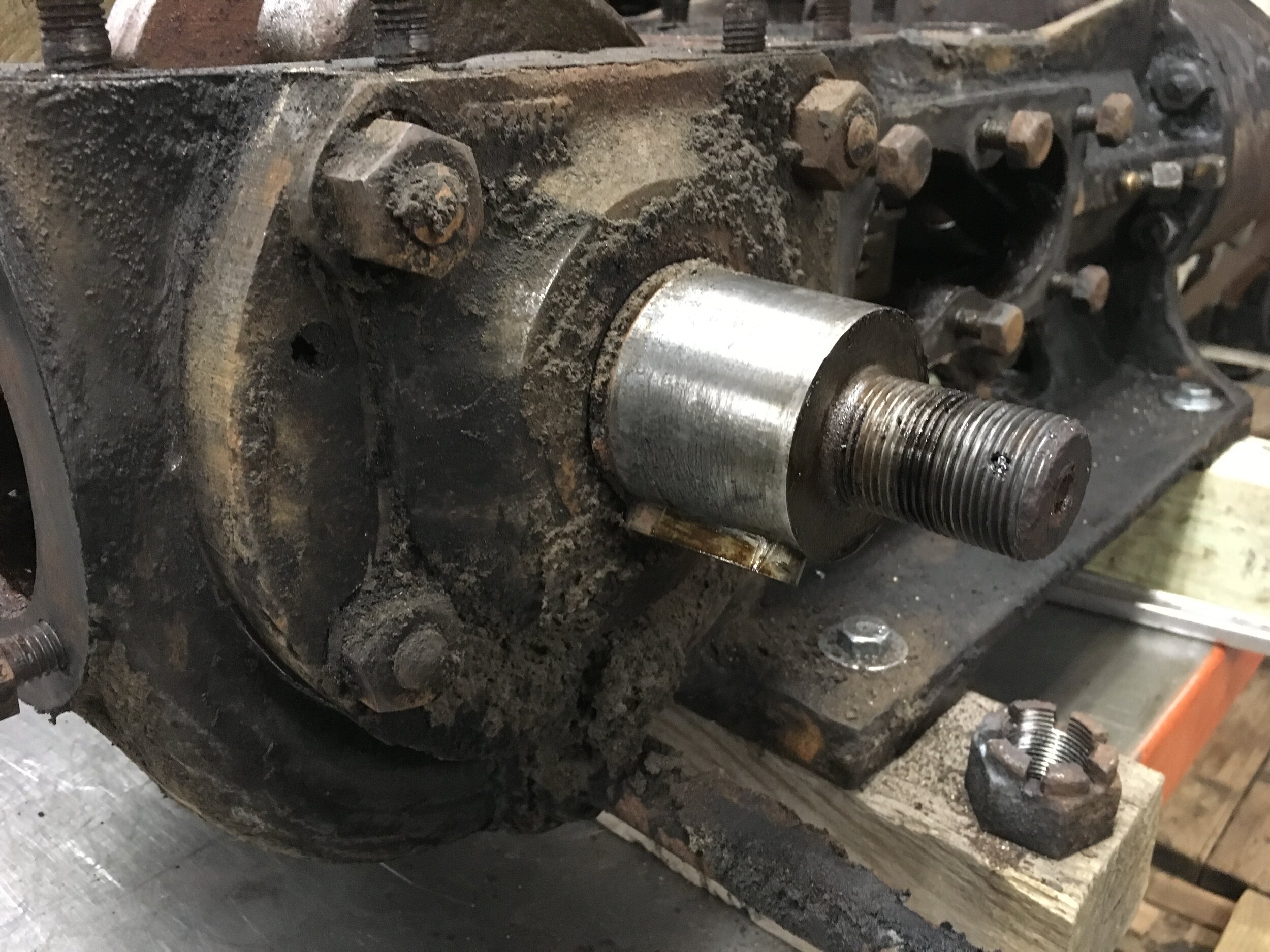

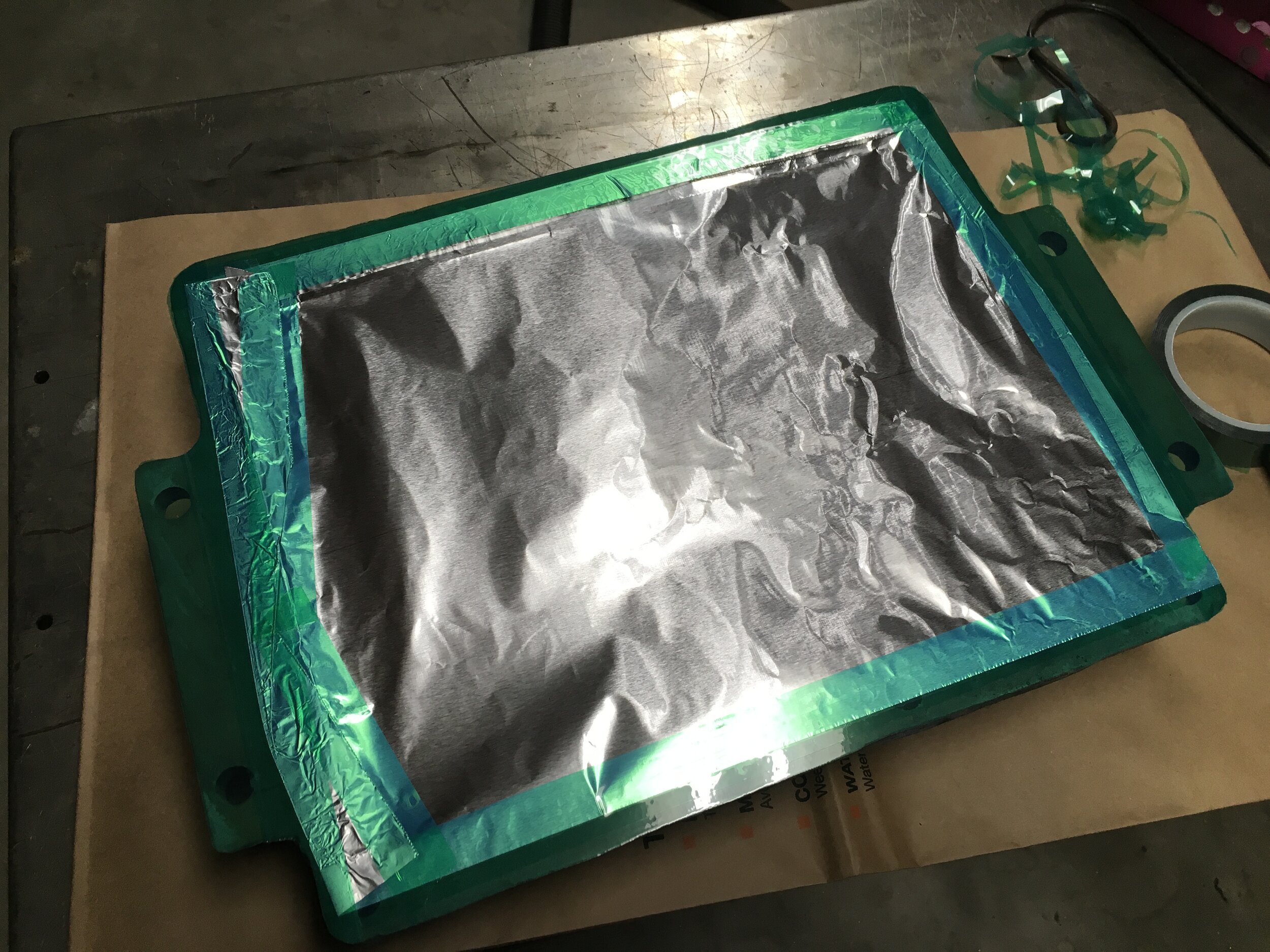

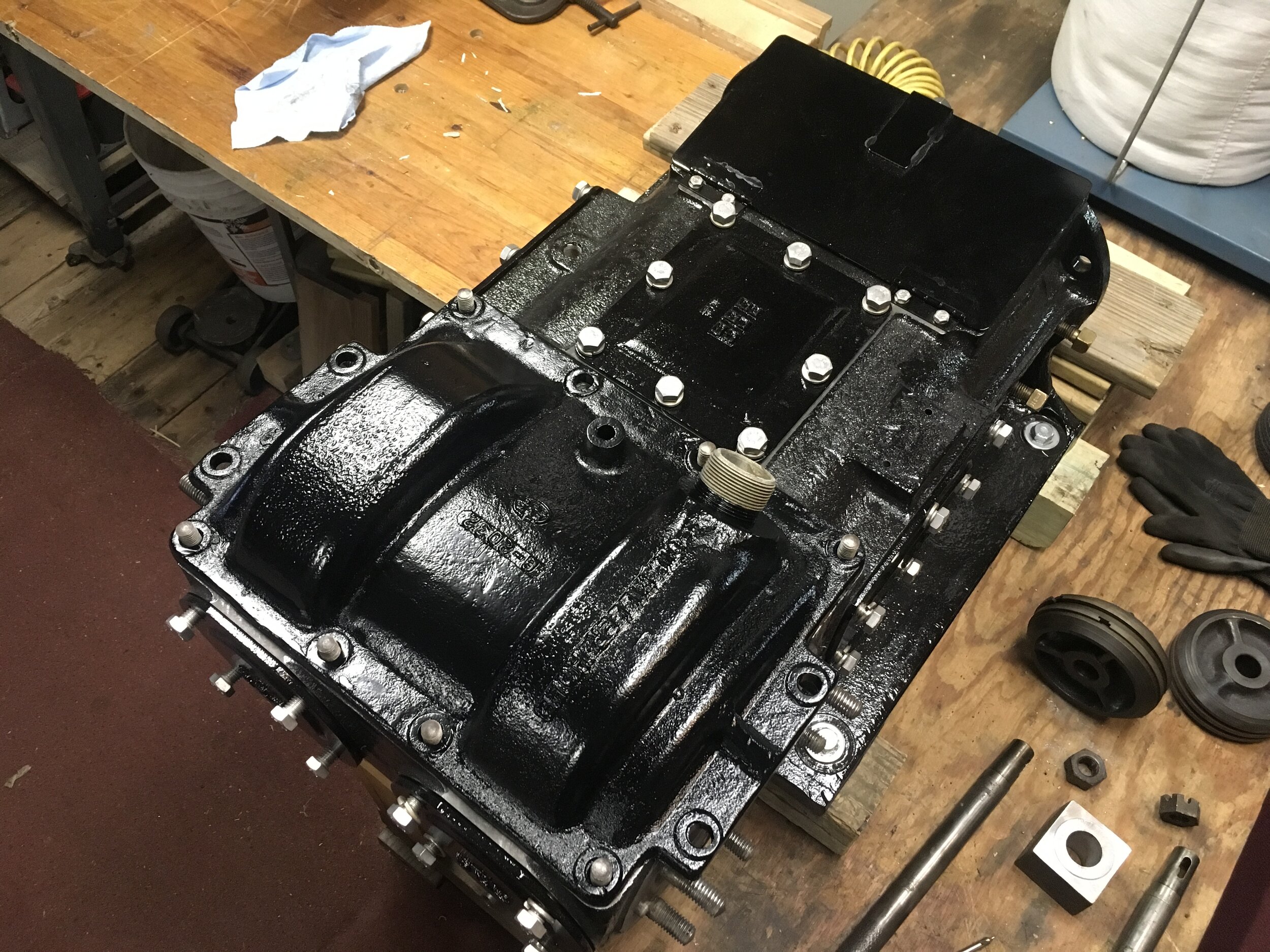

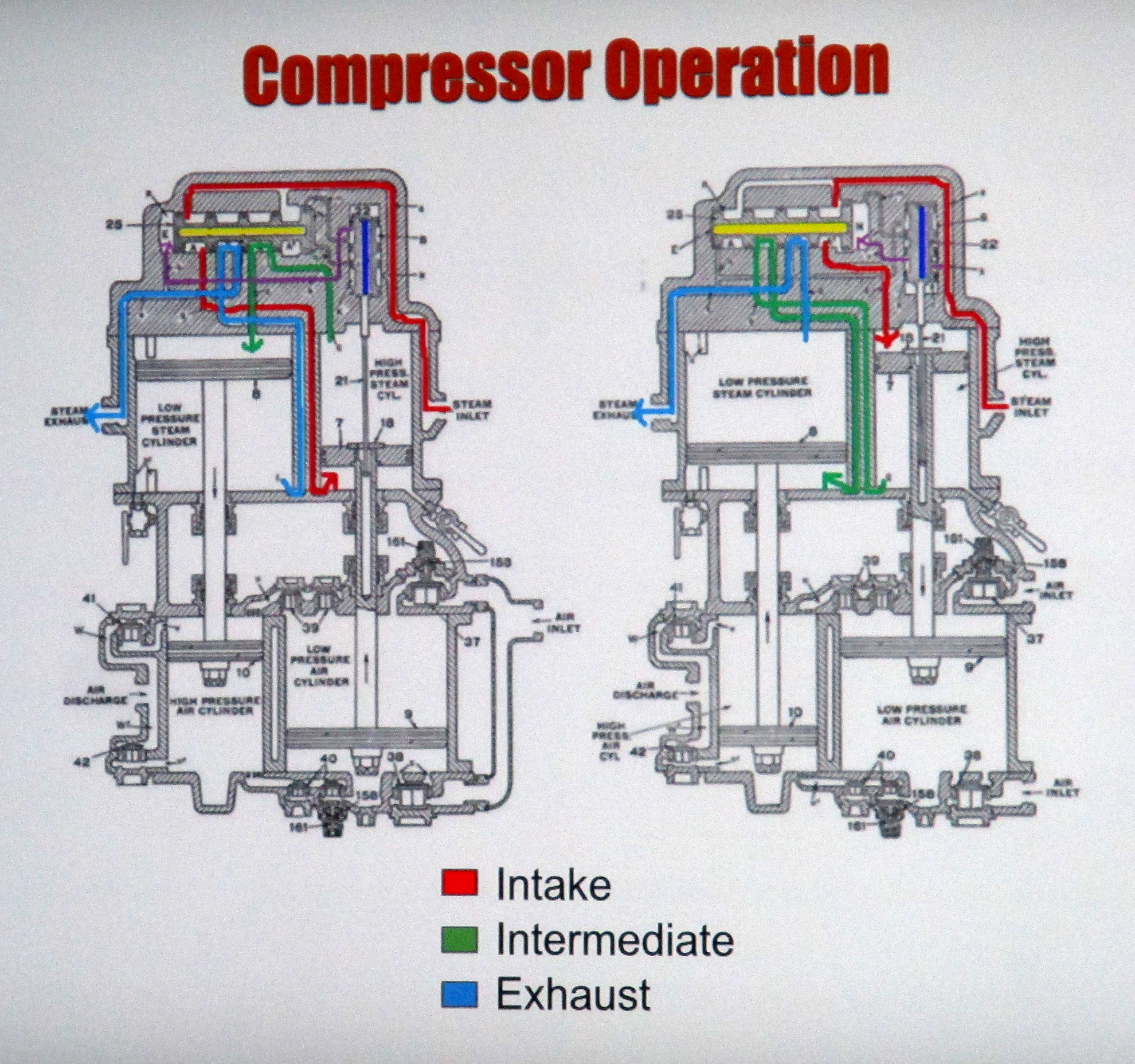

The Cross Compound Pump Engineering Team presented their capstone project before teacher and peer reviewers today (May 01). Each participant presented in turn with some specialized part of th project, but each was involved in the entire study. From L to R (2nd photo below - Jake Davee, Casey Roy, Ryan Lindsay, and Chris Dagget) posed with the mostly-completed Westinghouse air pump from 470. A crowd of approximately forty men and women observed. The project was so unique, as it delved into a heavy piece of machinery, once an off the shelf item, from a century ago. The students mastered the mechanical operation, cleaned and resurfaced the pump casting and arranged for $23,000 worth of donated services, parts and technical assistance during the semester. Each piece of the disassembled pump was cataloged, individually cleaned, examined, and reinstalled or replaced. Step-by-step journal notes were made for reassembly. One of the most impressive aspect of the presentation was Ryan's Solid Works exploded diagrams of the pump, showing the assembly and disassembly in an animated repeating diagram. Another animation showed the passage of steam and compressed air through the pump as it operated.

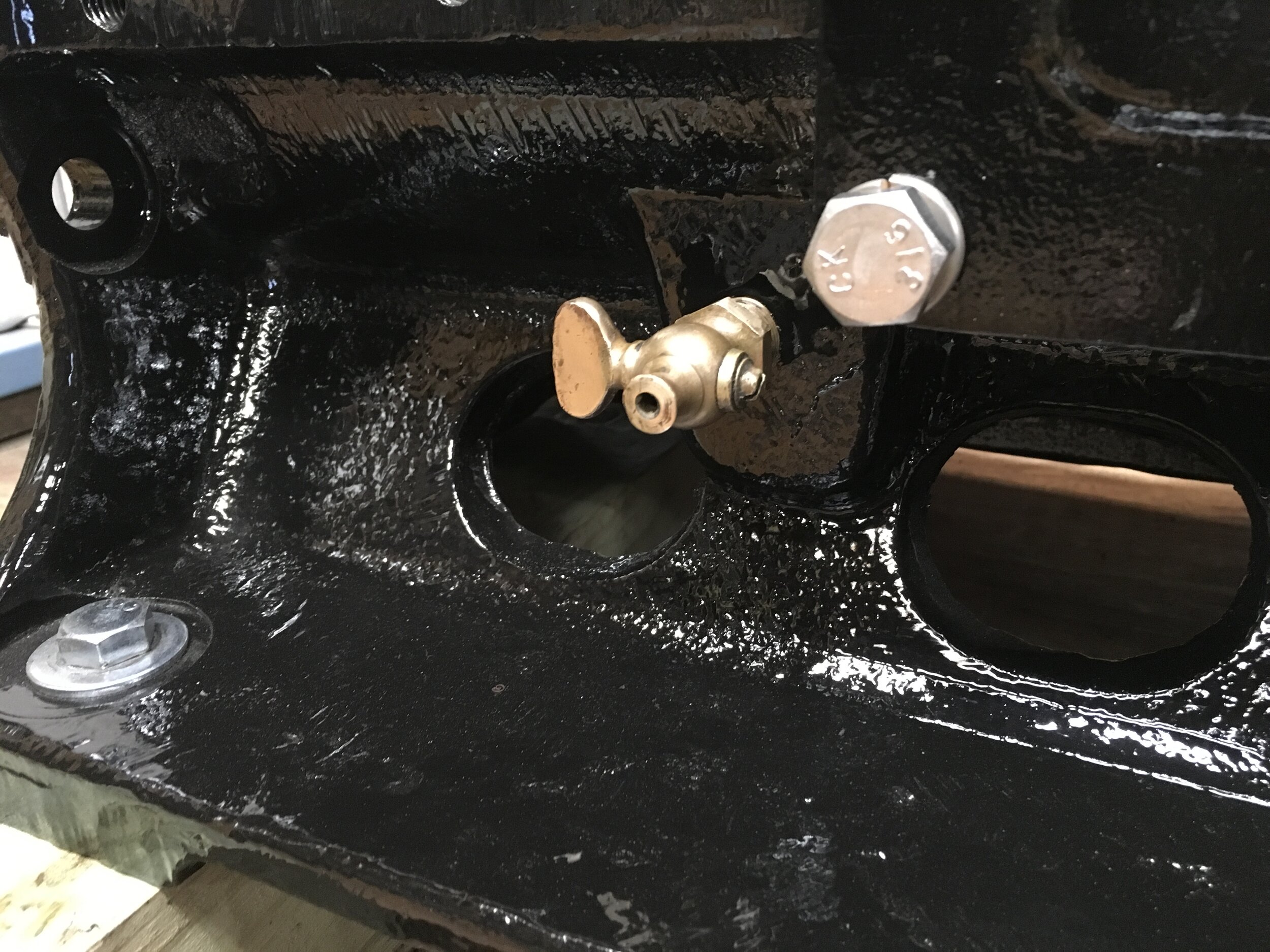

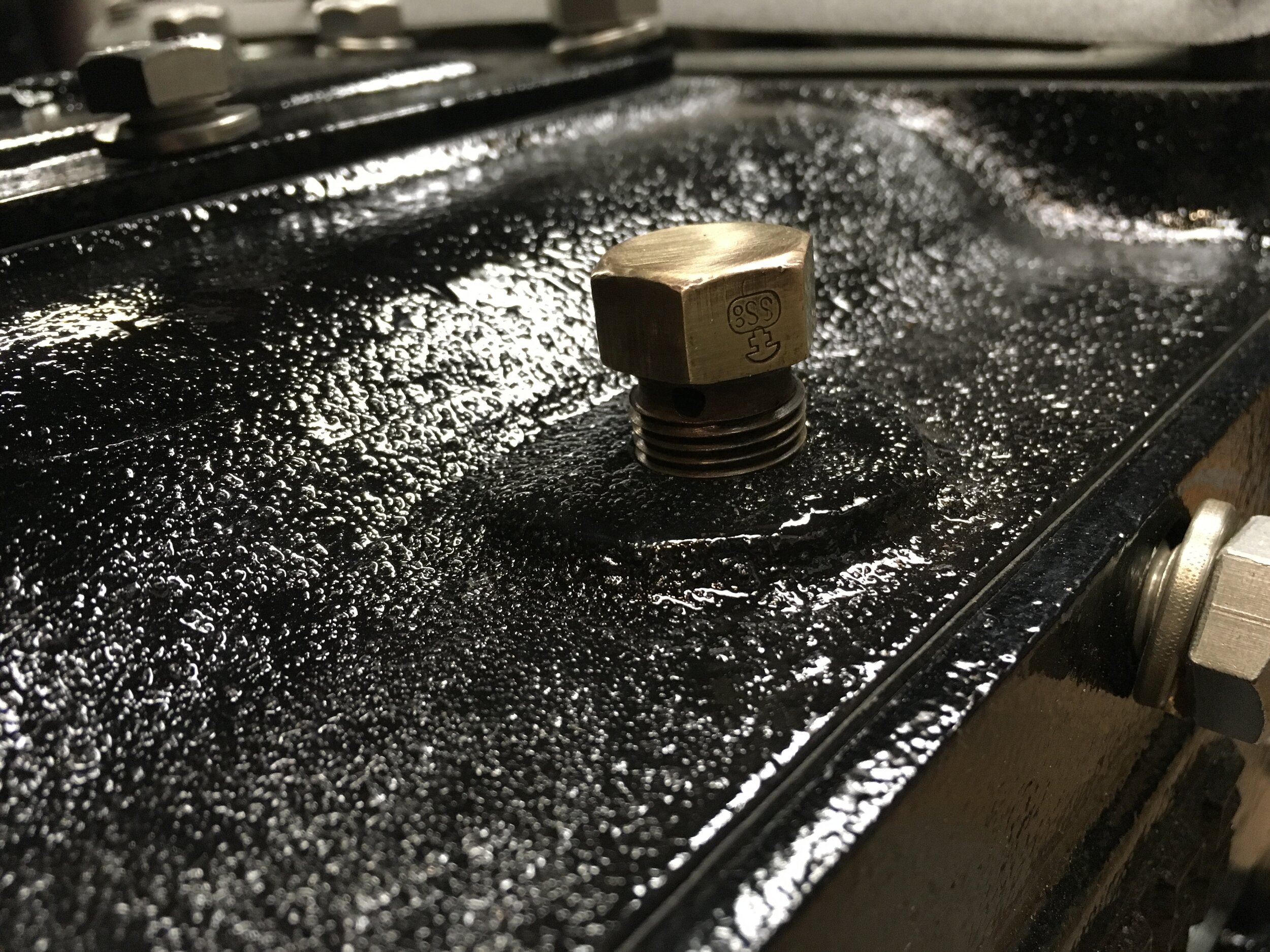

The pump lubricator is was completely rebuilt. It's a rather rather rare design, but it is 99% complete, requiring some new springs and a weighted flywheel crank handle.

Lessons learned: The team felt they should have gotten into the pump earlier in the semester rather than limiting their work to research on the front end. More time inside the pump and getting dirty with the hardware would have gotten them further into the machine without time constraints. Time management is a skill which was clearly stamped on their minds. Aside from that, they all had fun and learned hands on application in a real world problem solving experience. None of the team expressed regrets about undertaking the job.

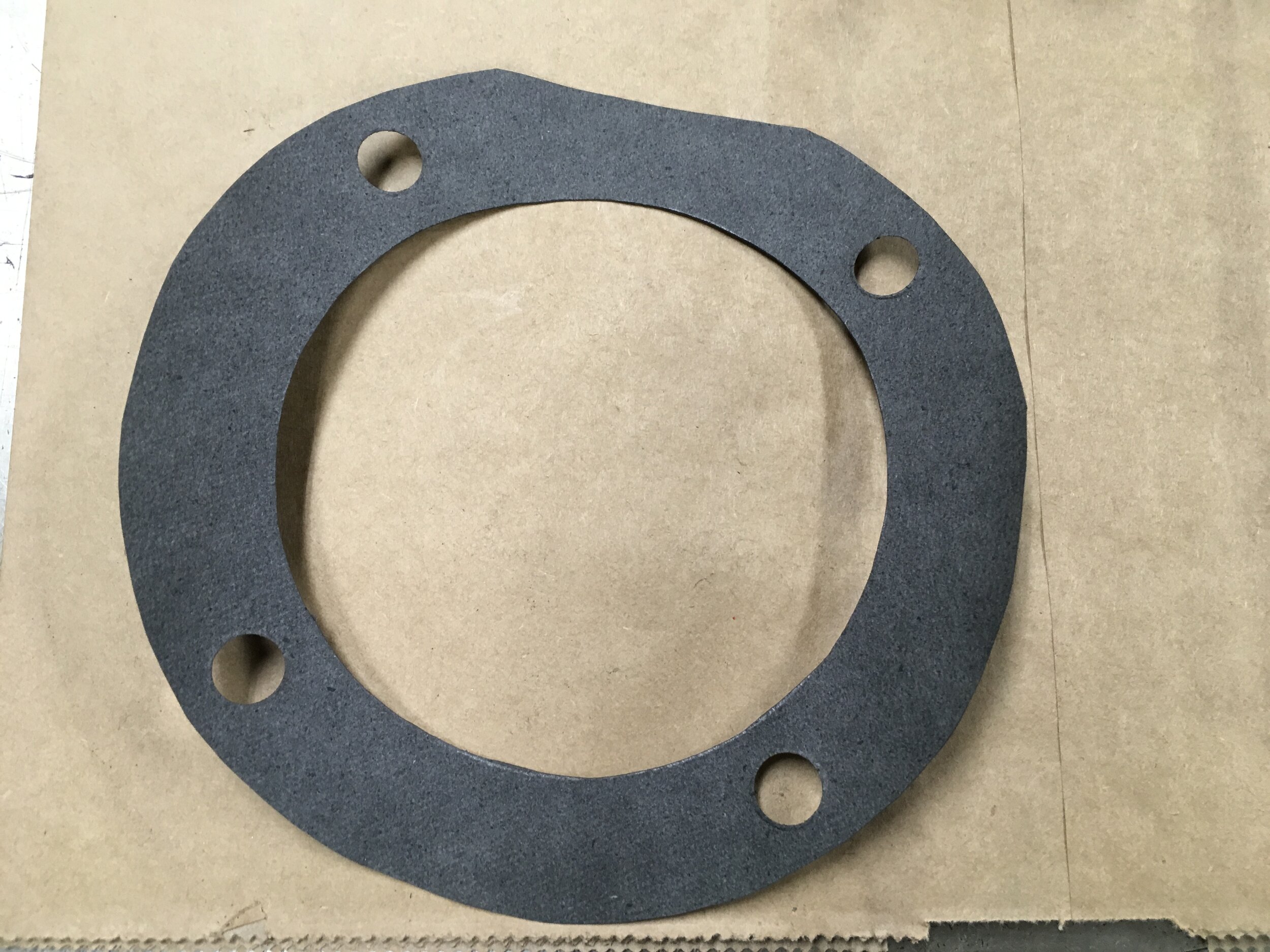

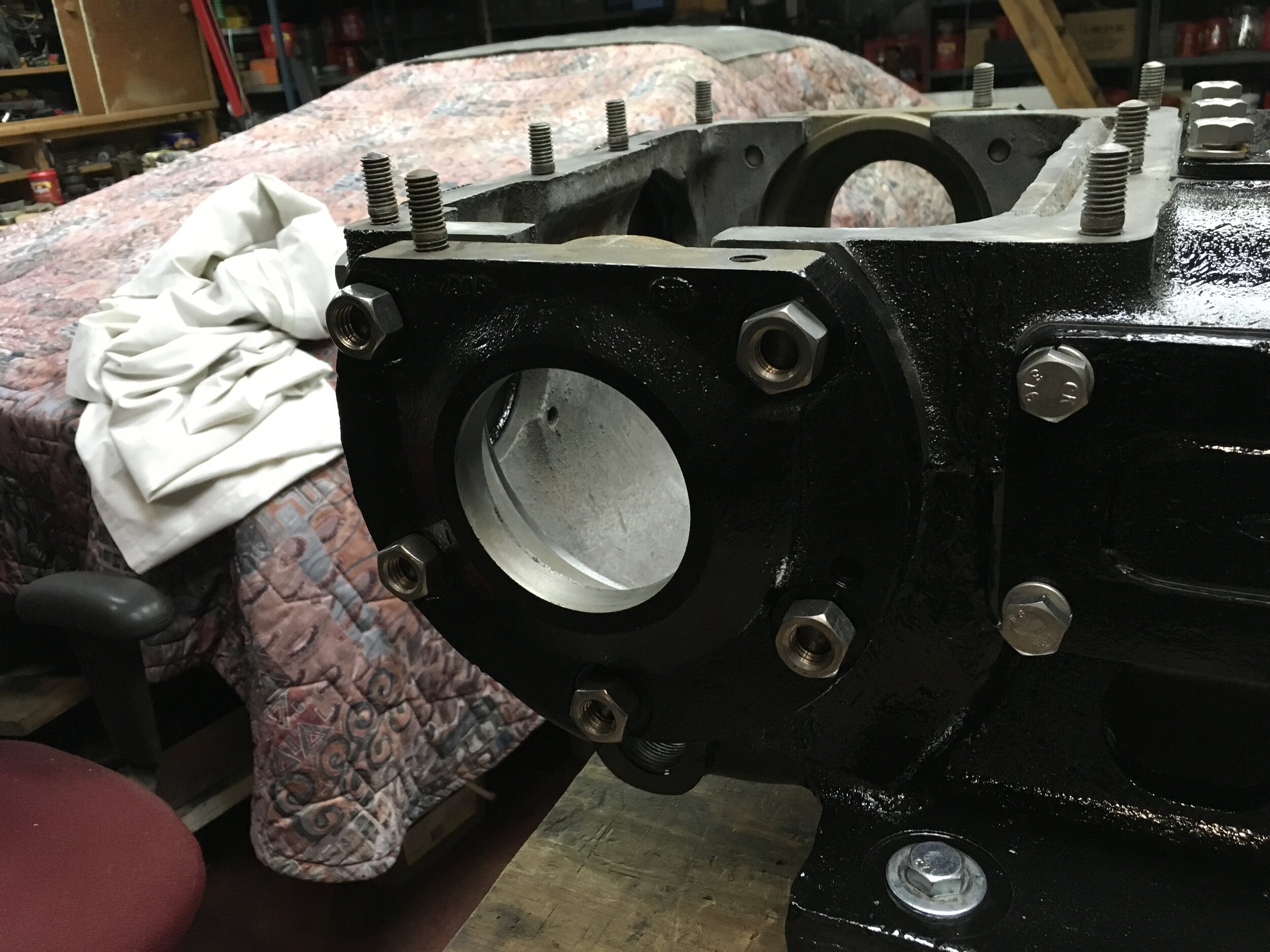

Is the pump finished? It's close, but the team ran into an issue with the cylinder bores. The top and bottom cylinders are not concentric and will require some sleeving to make them so. This was not the fault of the engineering team. NESCo will be looking to have this work completed in the near future so the pump can be lubed and made ready to install. Parts are in hand or on order, and the entire pump will be transferred back to NESCo's shop in Hancock, next week.

The team made a point of thanking Bernie Watts of Backshop Enterprises, the technical team at Steamtown, USA National Monument, and New England Steam's CMO Leverett Fernald. Without these three resources, the pump project would have been infinitely more difficult.

In the end, University of Maine Mechanical Engineering seniors, along with guided assistance from those mentioned above, saved the 470 restoration about $50,000 in labor and expense. Four young engineers will graduate into the professional labor pool with real life experience and real grease under their fingernails. New England Steam has opened our shops to the College of Engineering for students and field classes. The professors have invited NESCO to offer similar mechanical rebuild projects for future capstone project.