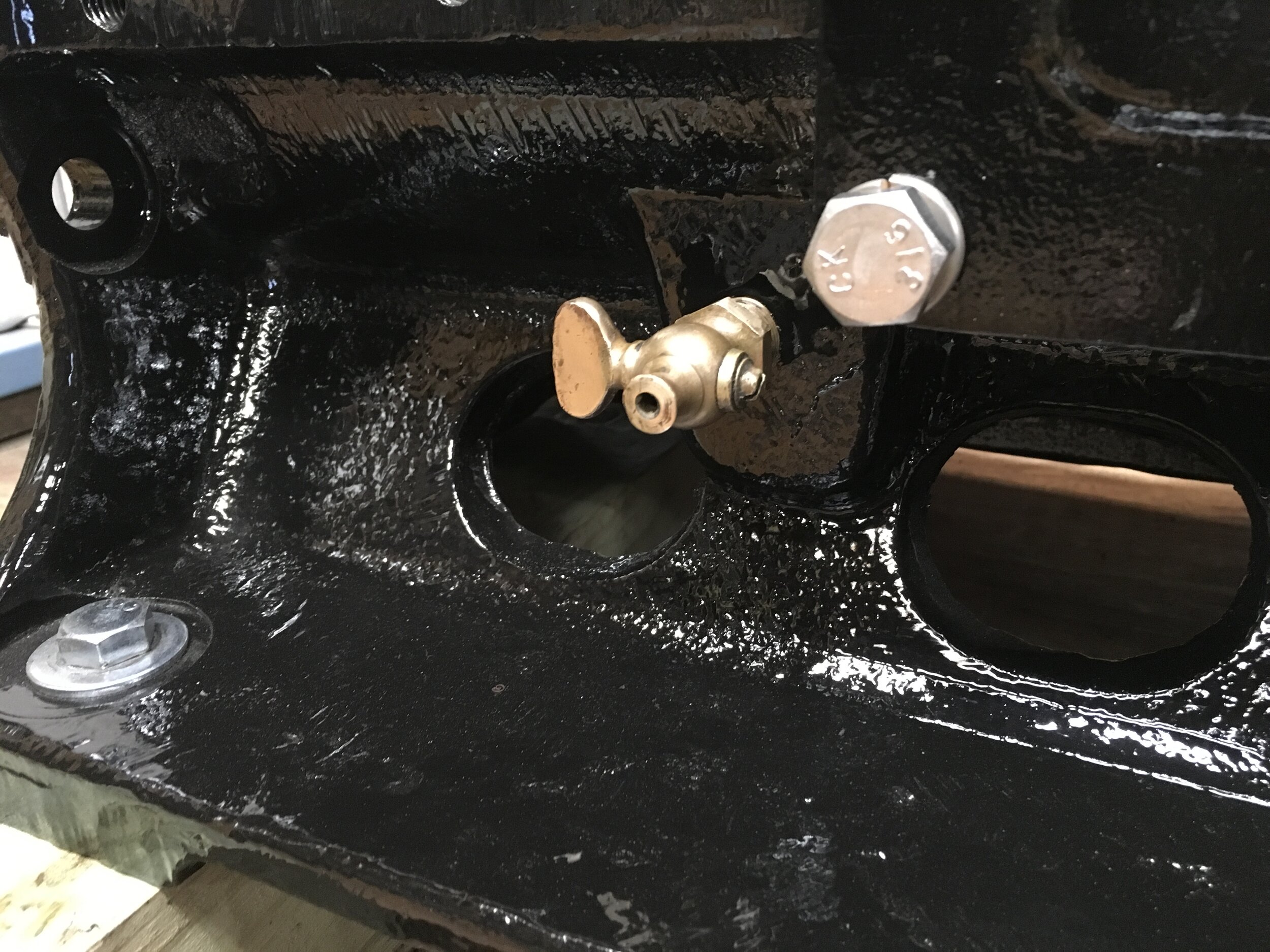

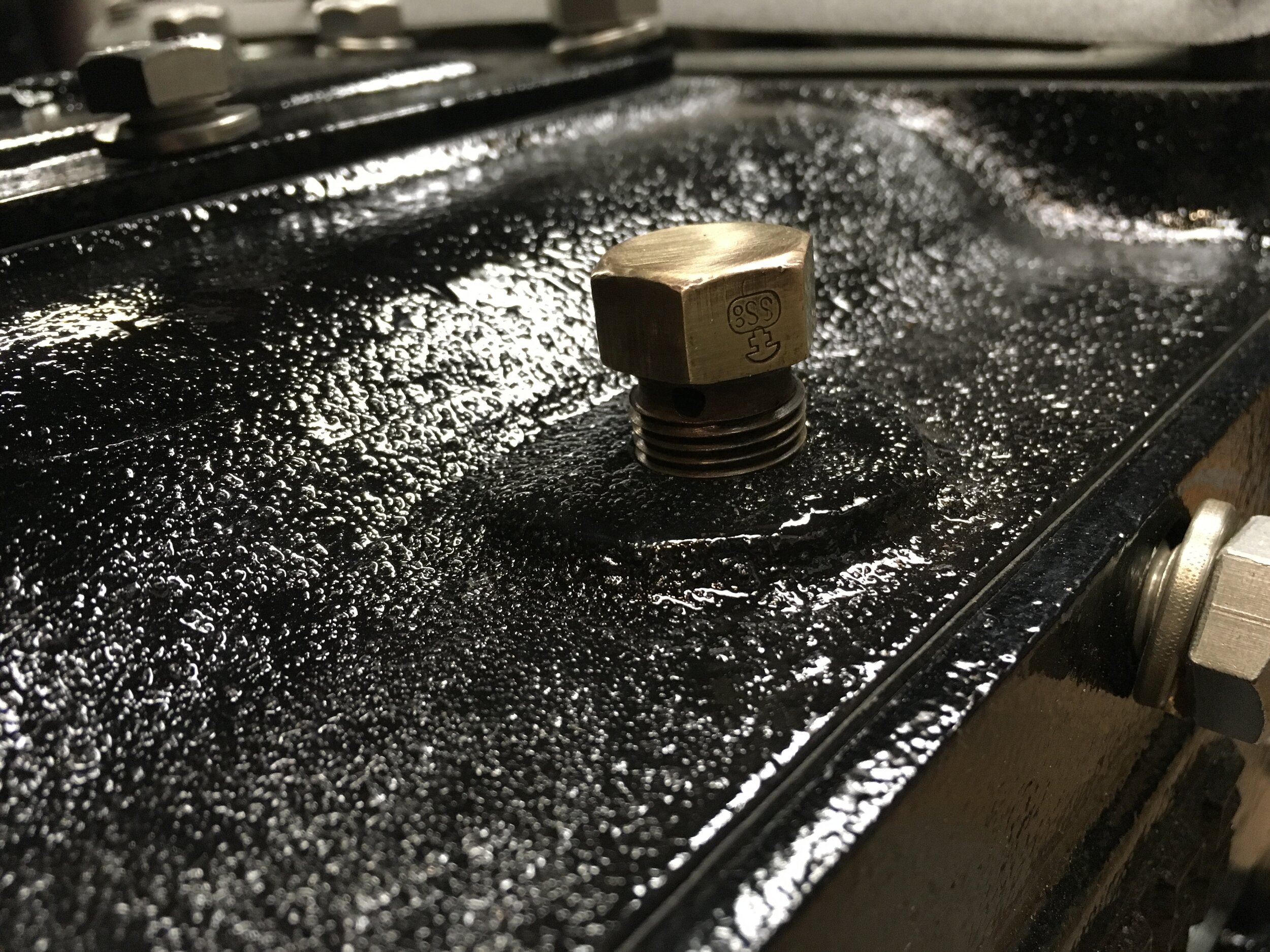

NESCo volunteer Bob DeWachter has been pretty busy at this! He powder coated the new oil breather, flywheel washer, steam port plug, and the locking fingers for the steam valve rod packing glands. He also refurbished the oil level try-cock. Pre-operational check, if oil comes out when open there is sufficient oil to run. And, he cleaned up the block vent. You can just make out the vent hole above the threads. Note the company logo and inspection stamp.

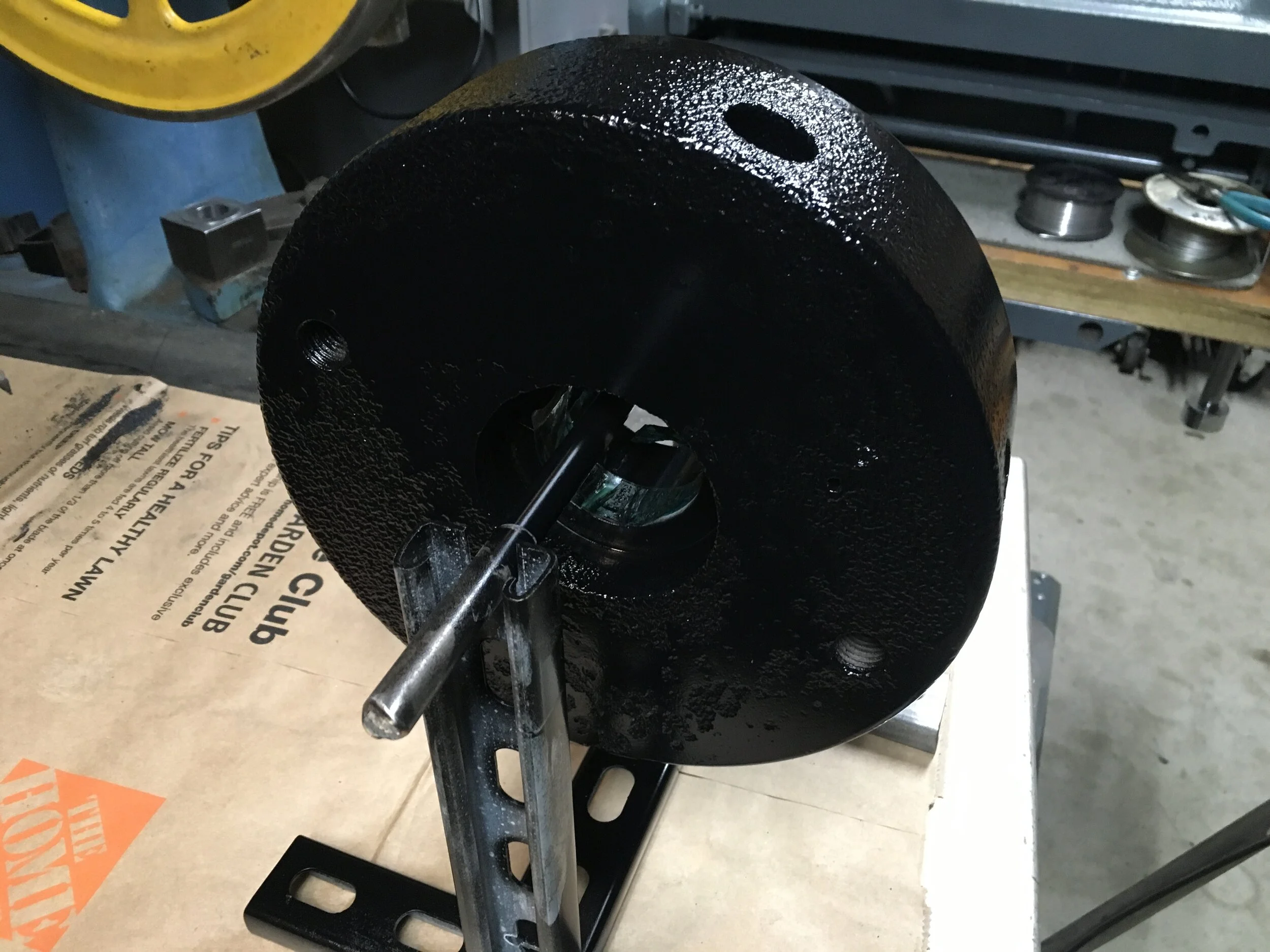

This is what the flywheel looked like upon removal. It took a bunch of time getting all the rust off and surface prep for powder coating. At nearly fifty pounds in weight, it took some doing to get it thru the process. The big break thru was making the stand to support the flywheel standing up. For the powder application, it just fit in the oven! About 2 hours of soak time to get to temperature, then 1/2 hour to bake. Then, nearly 4 hrs cooling down from 380 F. before Bob could handle it. There was quite heavy pitting on one side, but the back side was nice. Old grease/oil/dirt protected it.

Bob machined the two piston rods to remove the heavy rust pits. While conducting the machining setup, it became apparent that this had been done once during the engines service life, as 0.030” had previously been removed from the OD. Bob took another 0.032” to get to a 1.000” diameter.

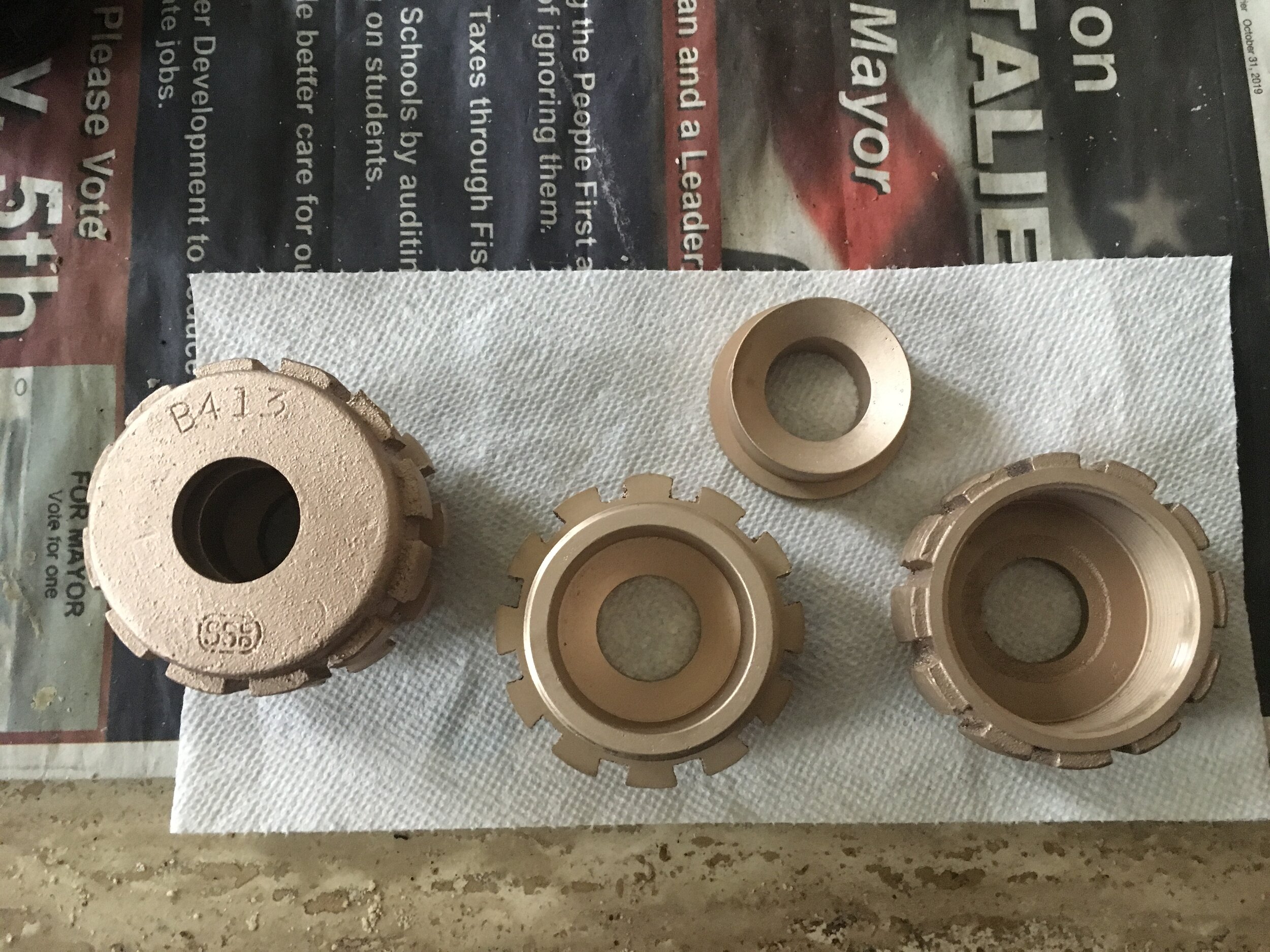

These are the piston rod packing assemblies. Bob used glass bead in his blast cabinet for these bronze parts. The soft packing has been removed. The internal bevels compress the soft packing to adjust tightness. The glands are turned with the red wrench it last weeks post. All four were cleaned up. The original packing is in great condition after all these years, but new packing will be fitted. The last photos show some test fit up. You can see the pair of brass gland lock screws on the left side.