Hit the 50's today in Hancock! Far cry from the 9 deg a few weeks ago. DESR had a crew in the shop working on the rebuild of one of their passenger car trucks. Meanwhile, Paul and Bob worked on 470’s cab, laying out rivet holes and testing a new tool!

What new tool? Bob DeWachter built a portable hydraulic rivet setting press from scratch in his home shop. Set up for 3/8” hot rivets, it makes short work of forming perfect spherical rivet heads. No assault on the senses like a big air hammer! Rivets are subjected to 12 tons of pressure via an air driven hydraulic pump controlled by foot. The press has proved easy to operate standing on a bench. With lots of handhold area, a crew will be able to hold it in place for many areas of the cab.

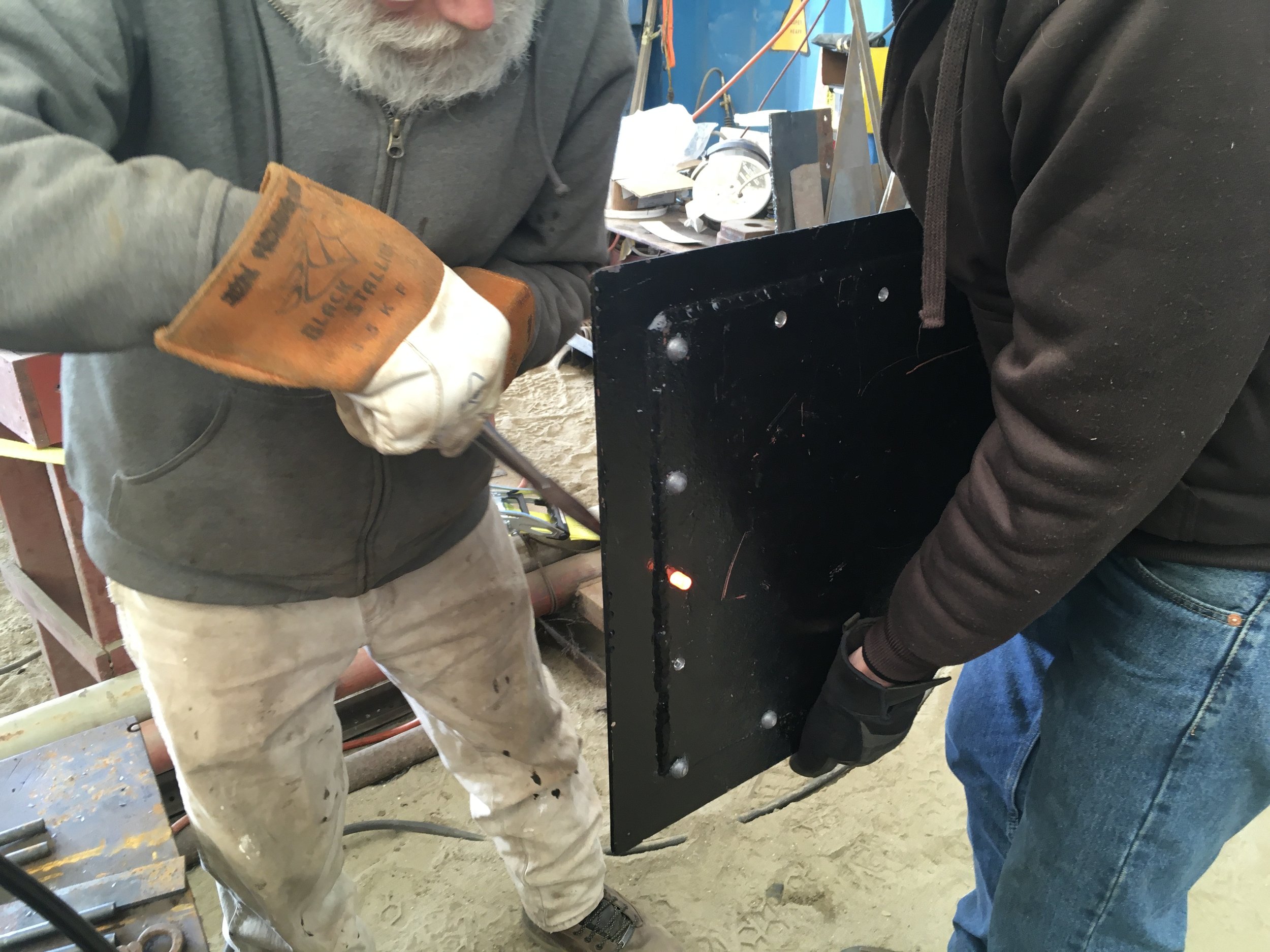

Its first job was to add rivets to one of the removable hatches on the tender. Bolt flanges were added to the panel shown here by welding. On this hatch, the rivets have been added for aesthetics. The other hatches will have only rivets used to attach the flanges. Best part, it only took about 1/2 hour to set all the rivets in this hatch, with no botched rivet heads and no earmuffs required.