Over the last two weeks, work has continued on the new office container. If you guessed that the color would be green, then you are correct! Paul has gotten one coat of paint applied and Bob ran more electrical outlets to make the space more functional.

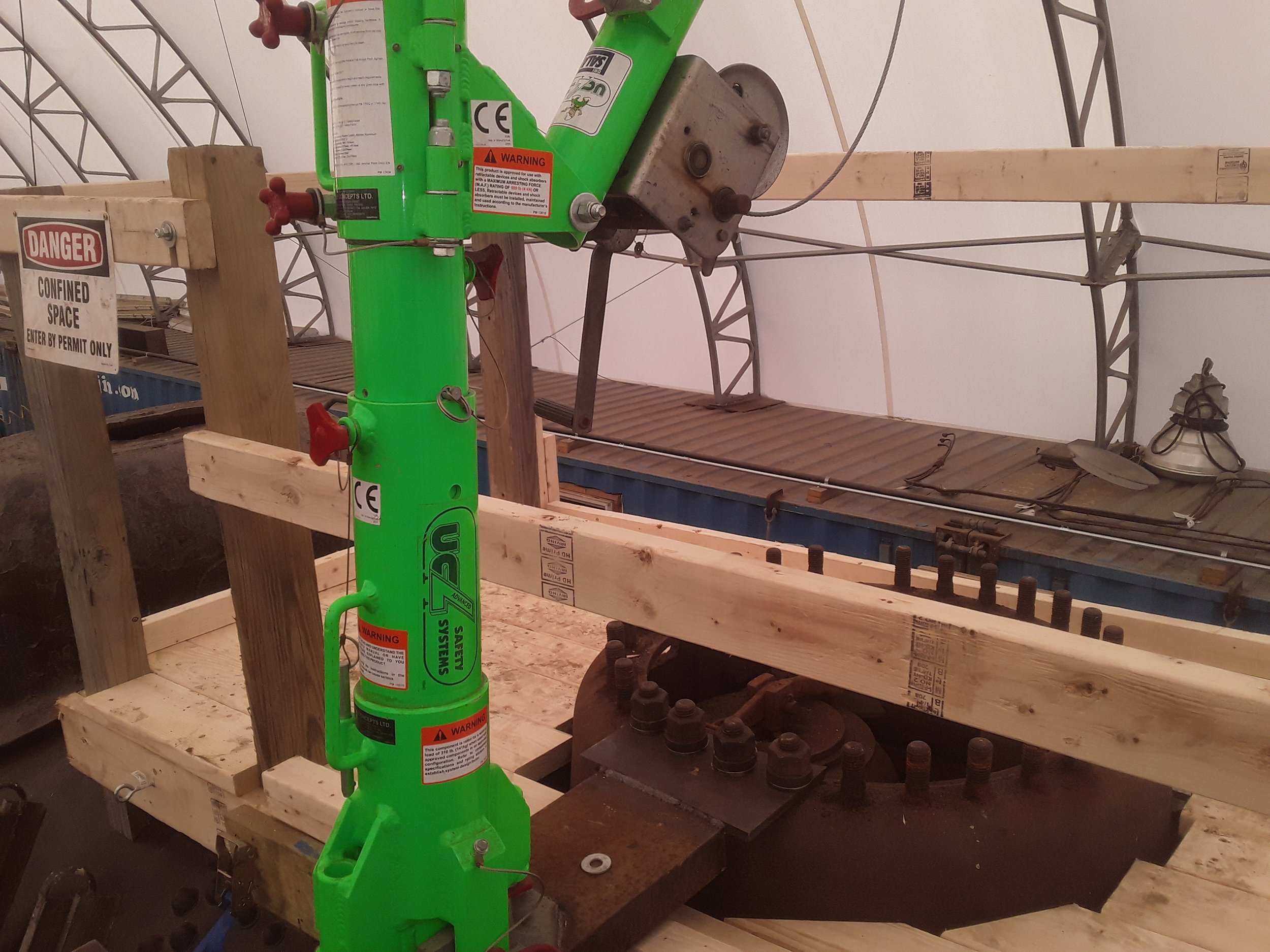

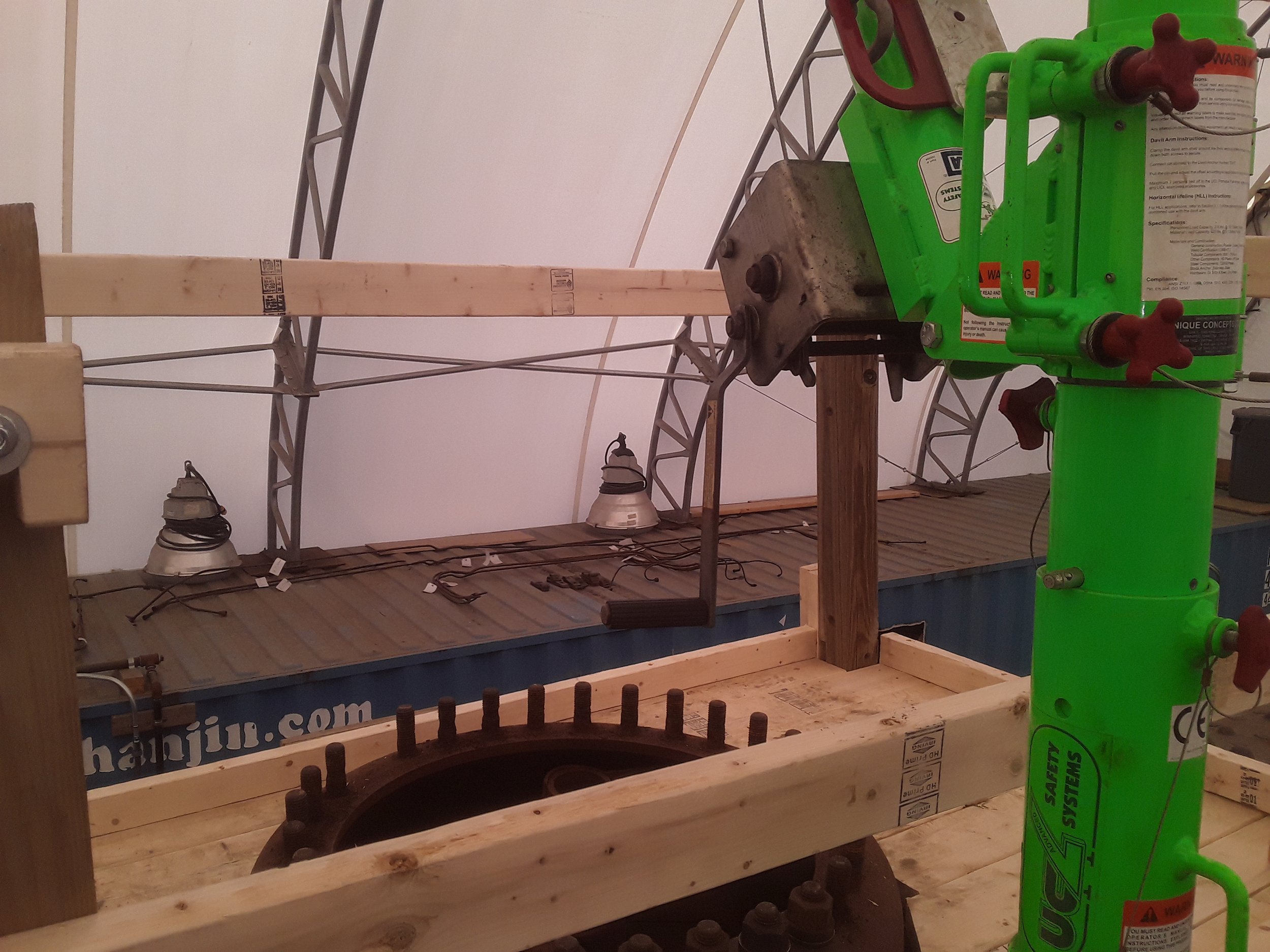

Work also progressed on the boiler. Timm finished the platform on top of the boiler so that crews may enter the dome safely. Some stray boiler tubes were discovered inside the tent, so Keith and Leverett moved them out to the pile. Leverett continued to work on mapping boiler studs. Brian and Hannah from Maine Locomotive & Machine Works came up Friday, April 7th and removed the wet patch off the backhead of the boiler. This “wet patch” had been applied by Maine Central to repair a leak. It was simply a steel patch formed to fit over the area that was leaking and it was welded around the edges and patch bolts applied in the center of the patch. We suspected a crack underneath it and after it was removed, our suspicions were confirmed (see photo). This type of repair is no longer acceptable and will require a different method of repair to be determined when the boiler survey is complete.

Additionally, Ron and Al continued drilling rivet holes. Keith and Leverett brought over a donated tool box and started organizing small hand tools. Keith also oiled the machinery on 470's frame, and Roger needlescaled small parts.

Present for work Sunday, April 2nd were Paul V, Ron and Al Jenkins, Timm Steele, Keith Thompson, and Leverett F.

Present for work Saturday, April 8th were Paul V, Bob, Ron and Al, Roger, and Leverett F.