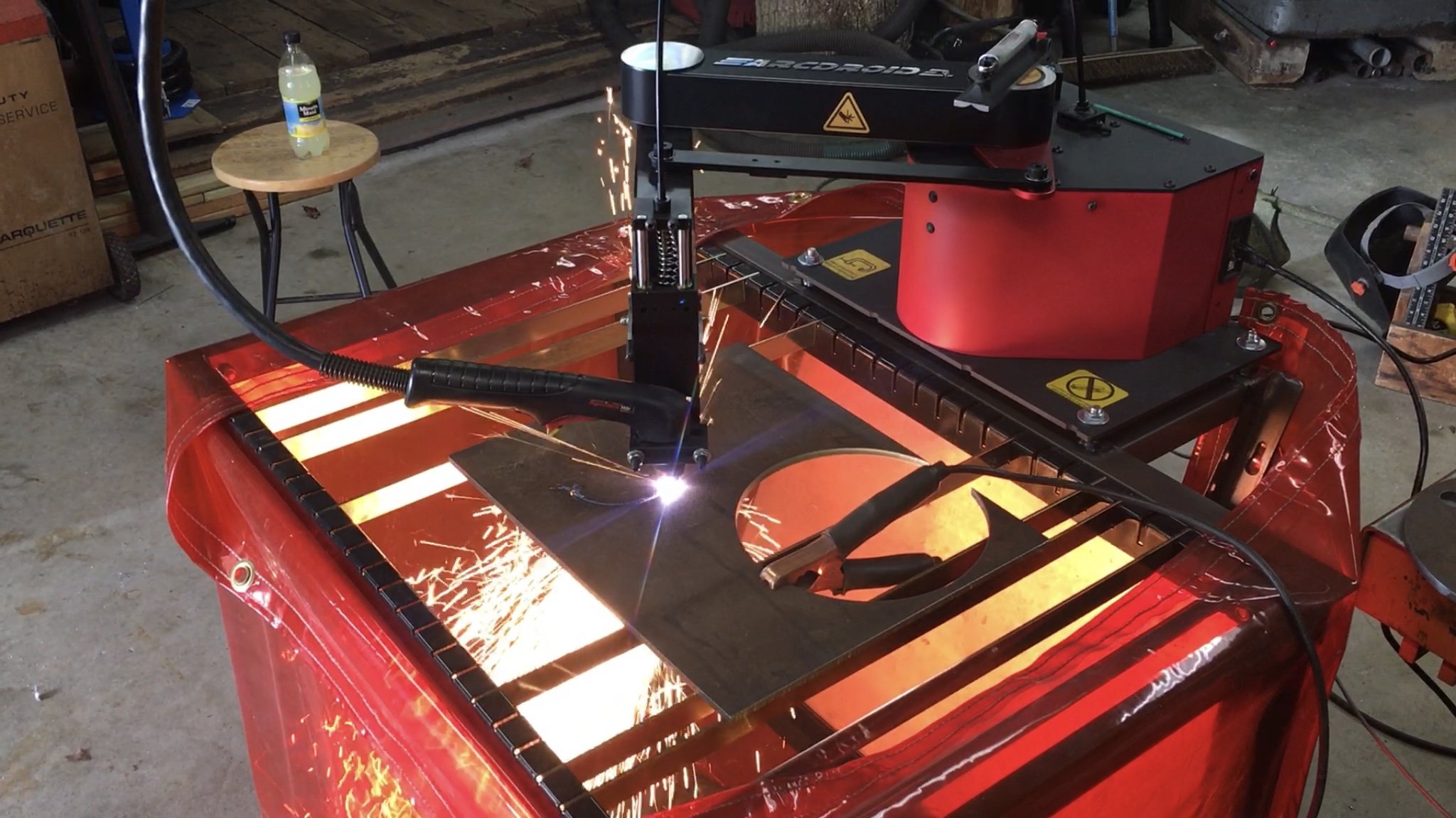

From the home shop of Bob DeWachter comes, new rapid metal fabrication! Using

his new CNC robotic arm plasma cutter, Bob fabricated two pipe flange backing plates to install the water connections on 470's new cistern. These plates sandwich the tank floor and allow installation without holding wrenches inside the tank and prevent any seepage around the bolt heads. The CNC cut from 1/4” steel plate at 60 inches per minute and took about 1:20 min to accurately cut the center hole, four 3/4” bolt holes and the outside diameter. A few moments cleaning up and Bob was ready to weld the bolt heads to the plate.

This plasma cutter is small and portable, and will allow rapid fabrication of most anything from metal stock. It really opens up possibilities for us and we are excited to explore where we can use it next!